Considérations pour les systèmes d’assemblage de toiture à membrane protégée (TMP)

Considérations pour les systèmes d’assemblage de toiture à membrane protégée (TMP)

Le choix d’un système d’assemblage de toiture à membrane protégée (TMP) dépend de différents facteurs qui détermineront la forme finale. L’expression « la forme suit la fonction » s’applique aussi aux toitures. Il est donc important de poser les questions suivantes...

• Quelle est l’utilisation principale de la toiture?

• Que désirent les propriétaires?

• Y a-t-il des considérations esthétiques?

• Y a-t-il des restrictions?

Le choix d’un assemblage de toiture à membrane protégée (TMP) dépend fortement de l’utilisation prévue. La membrane et l’isolant restent les mêmes pour tous les systèmes. Hydrotech propose différents système d’assemblage de toiture à membrane protégée (TMP) pouvant répondre aux exigences de presque toutes les conceptions:

Exigences structurales

Toutes les toitures doivent être conçues pour résister aux charges permanentes et aux surcharges qui y seront placées.

• Charge morte: poids du système d’assemblage de toiture et autres éléments permanents

• Charge vive: charges temporaires telles que le mobilier et les personnes

(la pluie et la neige sont considérées comme des surcharges)

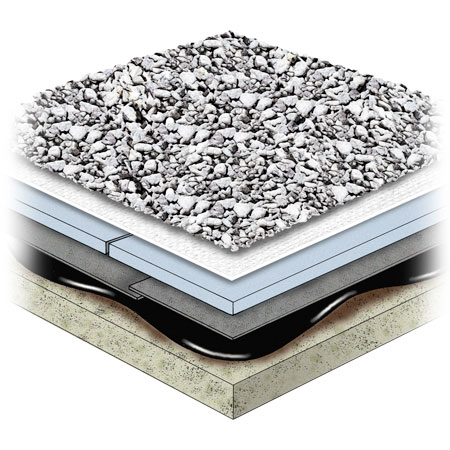

Le poids d’une TMP dépend des exigences de résistance aux vents de la toiture. Pour une toiture traditionnelle sous lest de pierre consulter le guide Tech Solutions 508.3 Ballast Design Guide for PMR Systems (CAN) de DuPont.

A basic PMR Assembly utilizes crushed or river washed stone as ballasting over the DuPont™ Brand Styrofoam™ Insulation. Stone provides weight to keep the insulation materials in place over the membrane. The amount of stone (or weight) needed is determined by the design wind uplift pressures on the roof. Typically, 10-13 pounds per square of stone ballast is needed in the field of the roof. Along the roof perimeter and in the corners where the uplift pressures are typically the greatest, 15-20 pounds per square foot of stone would typically be required. Enough stone must be used to completely cover the insulation and Stone Filter Fabric below. Stone used for ballast is graded in accordance with ASTM D448 and is typically referred to as #5,#4 or #2 stone.

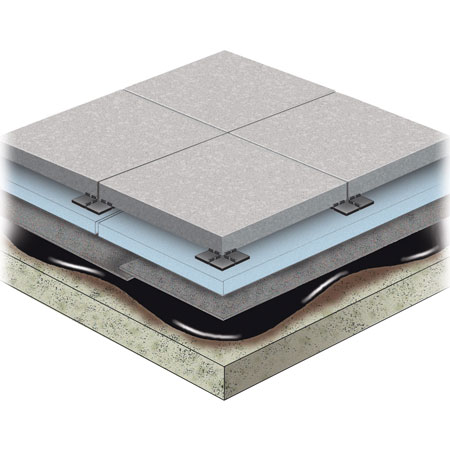

Concrete pavers are another commonly used material for ballasting a PMR Assembly. The typical concrete paver is a 24"x 24" x 2" unit, weighing a minimum of 22 pounds per square foot. If installed over the entire roof surface (or a minimum of 10% of the roof area), they must be set on support tabs to elevate them off the DuPont™ Brand Styrofoam™ Insulation. Concrete pavers are also used in conjunction with stone ballast to provide additional ballast securement at perimeters and in corners where the uplift pressures are typically greatest. At times it may even be necessary to secure one paver to another with metal strapping, running parallel to the building perimeter. Provided the pavers are less than 10% of the roof area they can be set directly on the DuPont STYROFOAM™ Insulation.

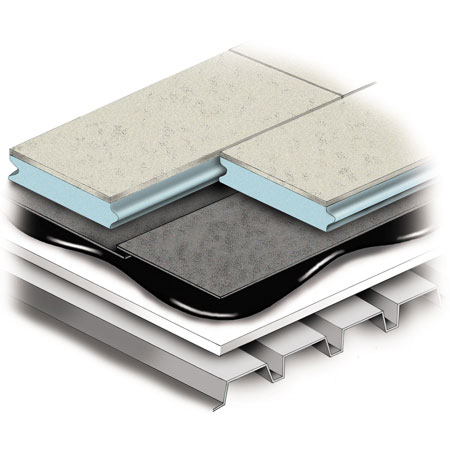

Hydroguard is a unique product, combining DuPont™ Brand Styrofoam™ Insulation with an integral concrete topping. The concrete ballast is a latex modified concrete that is physically and chemically bonded to the insulation. Hydroguard is available in panels 24" x 48" with either 2" or 3" insulation. Hydroguard Standard is available with a 3/8" thick concrete topping, which provides 4.5 pounds of ballast weight, per square foot. This is perfect over metal deck or other structures where weight may be an issue. Hydroguard Heavy is also available with a 15/16" thick concrete topping, providing 11 pounds of ballast weight per square foot and is ideal for roofs where more ballast weight is needed. Additional perimeter securement or ballasting is typically necessary with Hydroguard.

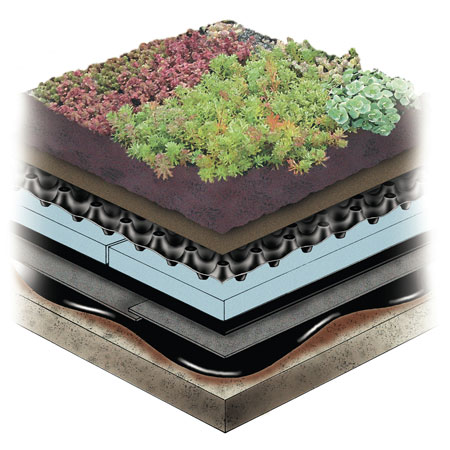

Hydrotech introduced the Garden Roof Assembly more than 20 years ago. Since that time Hydrotech has been involved in thousands of vegetated roofs of various types across the country. The typical Garden Roof Assembly weight can vary depending on the thickness and composition of the growing media and choice of vegetation and can be 17 LBS/SF and higher. An extensive Garden Roof provides many benefits; it’s beautiful yet extremely functional. Extensive vegetated roofs are increasingly used as a stormwater management tool. Properly designed they can detain and retain a great amount of the rainwater that might otherwise over burden existing storm sewer systems in of our older municipalities.